- Before turning off the power, dispose of the waste ink in the waste ink tank, and perform cleaning and [Custody Wash] for storage.

1. If the "Check Waste Ink Tank" error appears, please follow the steps below to replace it with

a new waste ink tank.

(1) On the LOCAL mode screen, select [MENU] > [Maintenance], then press the [ENTER] key.

(2) Select [Waste Ink Tank], then press the [ENTER] key.

(3) Select [Adjust Waste Ink Volume], then press the [ENTER] key.

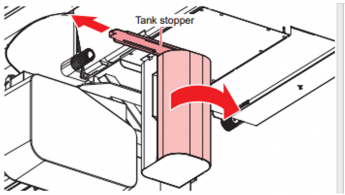

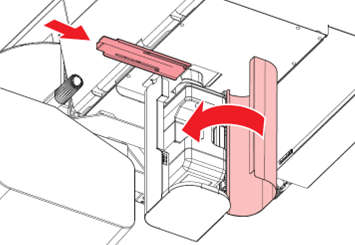

(4) Open the waste ink tank cover and unlock and pull the stopper forward.

* There is no tank stopper when using a plastic waste tank.

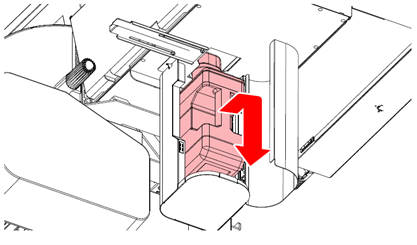

(5) Hold the handle on the waste ink tank and slide out.

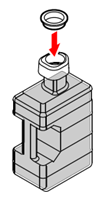

(6) Attach the cap to the removed waste ink tank, and use tape to prevent leakage of waste ink.

* Request an industrial waste disposal company to dispose of waste ink.

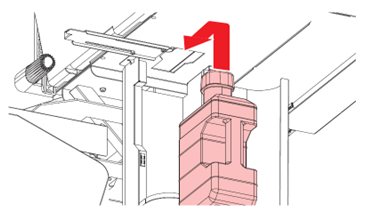

(7) Install a new waste ink tank.

(8) Return the stopper to its original position and close the waste ink tank cover.

* There is no tank stopper when using a plastic waste tank.

(9) Press the [ENTER] key.

The waste ink level will be reset.

2. Please perform cleaning of the lower part of the carriage.

(1) On the LOCAL mode screen, select [MENU] > [Maintenance], then press the [ENTER] key.

(2) Select [Station Maint.] > [Carriage Out] > [Move To Maint. Space], then press the [ENTER] key.

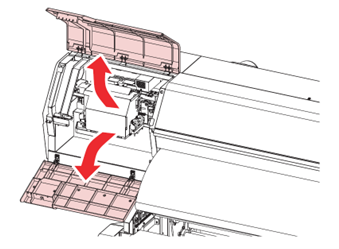

(3) Open the maintenance cover on the left side.

(4) Wipe off any ink adhering to the sides of the head and under the carriage.

Clean the print head sides using a cleaning stick.

(5) Press the [ENTER] key.

3. Execute [Custody Wash].

(1) On the LOCAL mode screen, select [MENU] > [Maintenance], then press the [ENTER] key.

(2) Select [Station Maint.] > [Custody Wash], then press the [ENTER] key.

(3) Open the maintenance cover on the right side.

(4) Clean the cover of the wiper unit.

Wipe off any ink and dust adhering using a cleaning stick moistened with maintenance liquid.

Wipe off the maintenance liquid. Make sure none remains.

Use the following maintenance liquid.

Item code: ML003-Z-K1

Item name: Washing liquid 03 Maintenance kit

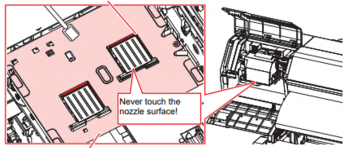

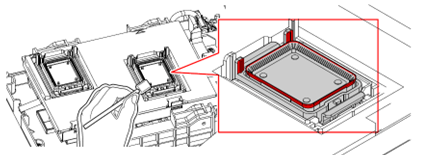

(5) Clean the cap rubber.

Wipe off any ink and dust adhering using a cleaning stick moistened with maintenance liquid.

Wipe off the maintenance liquid. Make sure none remains.

Clean the areas indicated in red (the entire interior and exterior of the cap rubber and the tabs)

in the diagram.

If ink dry matter adheres to the cap rubber, it may cause cleaning failure.

(6) Once cleaning is complete, close the cover, then press the [ENTER] key.

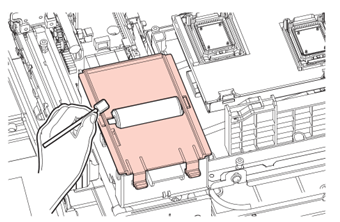

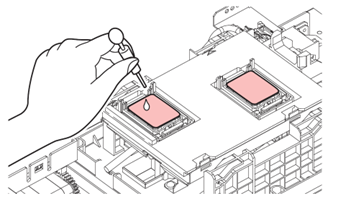

(7) When "Open the cover and check the maintenance liquid in the cap" is displayed,

open the maintenance cover on the right side and confirm whether the cap is

filled with maintenance liquid.

* If the maintenance liquid is not sufficient, use a syringe to draw maintenance liquid and fill the

cap until it is full.

Fill up the cap with maintenance liquid on the verge of overflow from the cap.

[Notes]

* Do not leave the media on the platen unattended. It may cause the media to become uneven.

* When not in use, please raise the clamp lever and keep the pinch roller and grid roller separated.

Leaving the pinch roller lowered for an extended period can cause deformation of the pinch roller.

If the pinch roller deforms, there is a risk that the media may not feed correctly.

[Important]

Please check the following to prevent ink path clogging and to protect the nozzles.

(1) Please keep the main power switch on during long-term storage.

The nozzle clogging prevention function works automatically to protect the printhead nozzles.

Leaving the main power turned off for a long period of time may cause the nozzles to be clogged.

(2) Check the remaining amount of ink packs and maintenance cleaning liquid cartridges.

During the cleaning operation, suction of cleaning liquid and ink will take place.

During ink suction, nozzle wash does not start if "INK END" or "INK NEAR END" is detected.

During the idle period, regular maintenance consumes ink and maintenance cleaning liquid.

Therefore, it is recommended to set ink packs and maintenance liquid cartridge

with sufficient remaining quantities.

If the remaining amount is low, please replace the maintenance liquid cartridge and ink pack.

Please also refer to these videos for reference.